Excavators are essential heavy-duty machines used in construction, mining, and various other industries for digging, lifting, and moving materials. Among the many components that contribute to their efficient operation, excavator bucket bushes play a crucial role. These small yet significant parts facilitate smooth movement and minimize wear and tear on the excavator's bucket assembly. In particular, the inner oil track type of excavator bucket bushes offers unique advantages and functions that are worth exploring.

The Basics of Excavator Bucket Bushings

Excavator bucket bushes are cylindrical components typically made of high-strength materials 40Cr. They are designed to fit into the pivot points of the excavator's bucket assembly, providing support and reducing friction during movement. These bushes act as bearings, allowing the bucket to articulate and pivot smoothly, even under heavy loads and harsh working conditions.

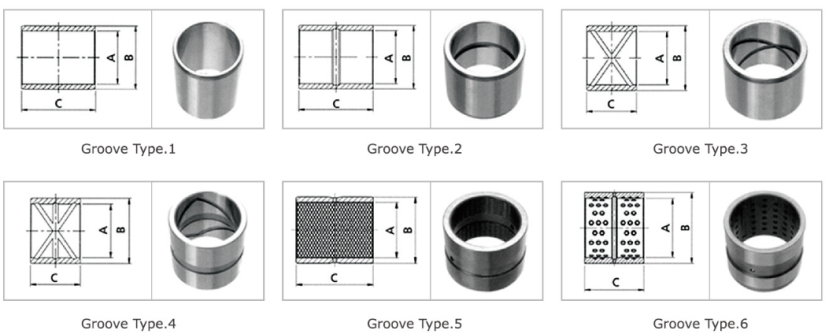

There are different types of excavator bucket bushes available, each with its own characteristics and advantages. One such type is the inner oil track bushing, which incorporates a specialized oil groove or track within its design. This feature sets it apart from standard bushes and enhances its performance in various ways.

bushings Structure and Functionality

The inner oil track type of excavator bucket bush features a unique internal design that includes channels or grooves specifically engineered to retain lubricating oil. These channels run along the inner surface of the bush, creating a continuous pathway for oil circulation. The presence of lubricant within the bushing helps reduce friction, dissipate heat, and prevent premature wear and tear.

The primary function of the inner oil track is to ensure adequate lubrication between the bushing and the pivot pin it surrounds. As the excavator operates, the movement of the bucket generates friction between these components. Without proper lubrication, this friction can lead to increased wear, heat buildup, and eventually, failure of the bushing.

By maintaining a constant supply of oil within the bushings, the inner oil track type effectively reduces friction and minimizes the risk of premature failure. The lubricant forms a protective barrier between the bushes and the pins, allowing for smooth articulation and prolonged service life of the excavator's bucket assembly.

Advantages of Inner Oil Track for Bushes

Improved Lubrication: The presence of the internal oil track ensures consistent lubrication throughout the bushing's operation, reducing friction and extending its lifespan.

Enhanced Durability: By minimizing wear and tear caused by friction, inner oil track bushings contribute to the overall durability and reliability of the excavator's bucket assembly.

Heat Dissipation: The lubricating oil helps dissipate heat generated during operation, preventing overheating and potential damage to the bushing and surrounding components.

Reduced Maintenance: With less friction and wear, excavator operators can expect reduced maintenance requirements and longer intervals between bushing replacements.

Smooth Operation: Proper lubrication ensures smooth articulation of the bucket assembly, allowing for precise control and efficient performance of the excavator.

Excavator bucket bushes, particularly the inner oil track type, play a vital role in the smooth operation and longevity of these powerful machines. By incorporating specialized oil grooves within their design, inner oil track bushings offer superior lubrication, reduced friction, and enhanced durability. These advantages make them indispensable components in heavy-duty excavators used across various industries. Understanding the functions and benefits of inner oil track bushings can help operators and maintenance professionals optimize the performance and reliability of their equipment, ultimately improving productivity and reducing downtime.